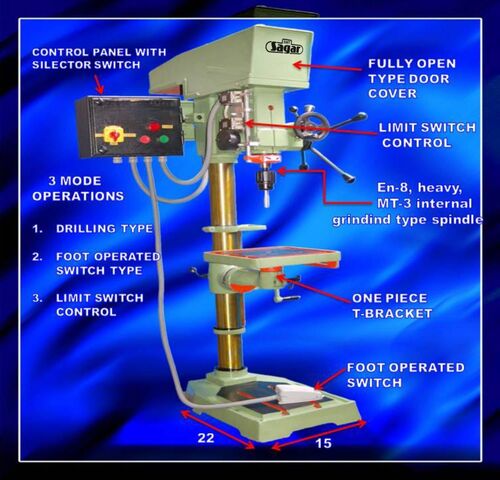

Tapping Cum Drilling Machine

Product Details:

- General Use Industrial use

- Computerized No

- CNC Or Not Normal

- Control System Manual

- Click to View more

Tapping Cum Drilling Machine Price And Quantity

- 1 Unit

- 60000 INR/Unit

Tapping Cum Drilling Machine Product Specifications

- Manual

- Industrial use

- No

- Normal

Tapping Cum Drilling Machine Trade Information

- Cash Advance (CA) Cash in Advance (CID)

- 100 Unit Per Month

- 1 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

Product Description

Sagar Machine Tools

Tapping Cum Drilling Machine

A tapping cum drilling machine is a versatile machine tool that combines the functions of both drilling and tapping. This type of machine is designed to perform drilling operations, where a rotating cutting tool is used to create holes in a workpiece, as well as tapping operations, which involve threading the inside of a hole to accept a screw or bolt.

Key features and functions of a tapping cum drilling machine include:

Drilling Operation: The machine is equipped with a spindle and a drill bit. It can be used for various drilling tasks, creating holes of different sizes and depths in a workpiece.

Tapping Operation: Tapping involves cutting threads into a drilled hole, allowing it to accept a threaded fastener.

Tapping cum drilling machines have the capability to perform tapping operations as well. This is useful in applications where threaded holes are required for bolts or screws.

Versatility: The combination of drilling and tapping capabilities in a single machine makes it a versatile tool suitable for a range of applications. It eliminates the need for separate machines for drilling and tapping processes.

Automatic Feed: Many tapping cum drilling machines come with automatic feed mechanisms that control the rate at which the drill or tap advances into the workpiece. This feature helps improve efficiency and consistency in the machining process.

Adjustable Speed and Depth: These machines often have adjustable speed settings to accommodate different materials and drill bit or tap sizes. Additionally, they may allow users to control the depth of drilling or tapping for precision work.

Table and Workpiece Clamping: Tapping cum drilling machines typically have a worktable where the workpiece is secured. The table may be adjustable to accommodate different sizes of workpieces. Proper clamping mechanisms ensure stability during machining.

Power Source: These machines are usually powered by electric motors, providing the necessary power for both drilling and tapping operations.

Coolant System: Some machines may be equipped with a coolant system to lubricate and cool the cutting tools during the machining process. This helps extend tool life and improve the quality of the machined surfaces.

Tapping cum drilling machines find applications in various industries, including manufacturing, metalworking, and fabrication, where the creation of precise holes with threaded capabilities is necessary. The choice of a tapping cum drilling machine depends on factors such as the type of materials to be machined, the size and depth of the holes required, and the overall production requirements.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry Send SMS

Send SMS