Heavy Duty Socket Type Drill Machine

Price 7500 INR/ Unit

Heavy Duty Socket Type Drill Machine Specification

- Spindle Speed

- 150-1800 RPM (variable)

- Dimension (L*W*H)

- 650 x 300 x 800 mm

- Features

- Heavy duty, durable construction, precision drilling, adjustable table

- Motor Power

- 2 HP (Single/Three Phase)

- Cutting Area

- Versatile, variable

- Noise Level

- Low

- Machine Type

- Socket Type Drill Machine

- Frequency

- 50 Hz

- Condition

- New

- Diameter

- Max 25 mm

- Table Size

- 250 x 250 mm

- Product Type

- Heavy Duty Socket Type Drill Machine

- Material

- Stainless Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- Normal

- Control System

- Manual

- Voltage

- 220-240 V

- Power

- 2 HP

- Power Source

- Electric

- Weight (kg)

- Approx. 95 kg

- Capacity

- Up to 25 mm (drilling diameter)

- Color

- Green & Black

- Usage & Applications

- Metal drilling, workshop, industrial drilling operations

- Drive Type

- Belt Drive

- Coolant System

- Optional

- Column Diameter

- 80 mm

- Phase

- Single/Three phase available

- Drilling Depth

- 125 mm

- Base Size

- 385 x 255 mm

- Spindle Travel

- 125 mm

- Chuck Size

- 13 mm

Heavy Duty Socket Type Drill Machine Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Heavy Duty Socket Type Drill Machine

Heavy Duty Socket Type Drill Machine is a powerful tool utilized for drilling into various materials such as wood, metal, masonry, and concrete. This machine has a keyless chuck that can be easily changed to accommodate different drill bit sizes, and it works by applying a high-speed rotary force with a back-and-forth hammering motion to break through tough surfaces. The socket type design of the machine allows for the application of high torque output and provides a more secure grip on the drill bit. Heavy Duty Socket Type Drill Machine is essential to wear appropriate safety gear and follow proper operating procedures to avoid accidents while using the drill machine.

Precision Drilling for Industrial Demands

Built with a heavy-duty frame and adjustable table, this drill machine meets the high standards required in metal workshops and manufacturing setups. Its spindle travel, stable base, and versatile cutting area allow for controlled and accurate drilling up to 25 mm diameter. The low noise level and ergonomic design improve operational comfort and productivity.

Versatile Power Options

Compatible with both single and three-phase electrical set-ups, the machine is adaptable to various workshop requirements. With a voltage rating of 220-240 V and a frequency of 50 Hz, it delivers consistent performance throughout extended usage. The belt drive and manual controls let users fine-tune speed and pressure for diverse drilling tasks.

User-Friendly Features and Applications

Ideal for metal drilling in workshops, industrial plants, and manufacturing units, this semi-automatic drill is designed for easy handling. Its green and black finish enhances visibility and safety. The adjustable table and optional coolant system allow users to customize the process to specific workpieces or prolonged operation.

FAQ's of Heavy Duty Socket Type Drill Machine:

Q: How is the drilling depth achieved with this socket type drill machine?

A: The machine offers a spindle travel of 125 mm, facilitating a maximum drilling depth of 125 mm. The manual control system enables users to precisely manage the drilling process to reach the desired depth.Q: What materials can be drilled with this heavy-duty drill machine?

A: This drill is constructed from stainless steel and is specially designed for metal drilling. It efficiently handles a range of industrial metals, offering precise results suitable for workshops and manufacturing sites.Q: When should the optional coolant system be used during drilling?

A: The coolant system is recommended for prolonged or intensive drilling applications, particularly when working with tougher metals. It helps to manage heat generation, improving tool life and maintaining drilling accuracy.Q: Where is this drill machine typically installed and used?

A: This machine is ideally used in metal workshops, fabrication plants, and industrial environments across India. Its robust construction and adjustable components make it suitable for various drilling stations and workbenches.Q: What is the process for adjusting spindle speed and table position?

A: The spindle speed, which ranges from 150 to 1800 RPM, is adjusted through the belt drive mechanism. The table can be manually repositioned to accommodate different workpiece sizes and angles for versatile drilling operations.Q: How does this machine benefit workshops and industrial users?

A: Featuring a durable build, variable speed, and adjustable components, this drill machine delivers consistent precision and efficiency. Its low noise operation and ergonomic design enhance user comfort, while its power options allow compatibility with different electrical supplies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Drill Machine Category

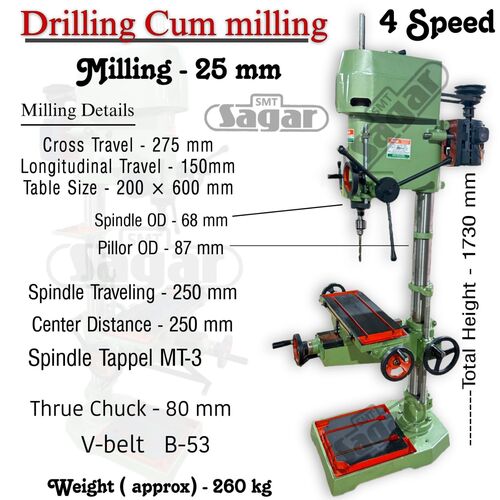

Drilling Cum Milling Machine

Price 62000 INR / Unit

Minimum Order Quantity : 1 Unit

Noise Level : Low

Machine Type : Universal Drilling Cum Milling Machine

Color : Blue & White

Frequency : 50/60 Hz

19mm Pillar Drill Machine

Price 17000 INR / Unit

Minimum Order Quantity : 10 Units

Noise Level : Low

Machine Type : Vertical Pillar Drill

Color : Green

Frequency : 50 Hz

25mm Pillar Drill Machine

Price 17000 INR / Unit

Minimum Order Quantity : 10 Units

Noise Level : Low

Machine Type : Pillar Drill

Color : Grey

Frequency : 50 Hz

32mm Pillar Drill Machine

Price 36000 INR / Unit

Minimum Order Quantity : 10 Units

Noise Level : Low

Machine Type : Pillar Type

Color : Grey / Metallic

Frequency : 50 Hz

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS