Mechanical Shearing

Price 360000 INR/ Unit

Mechanical Shearing Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Mechanical Shearing

Mechanical Shearing

It seems like you are referring to a mechanical shearing machine with a cutting capacity of 4 feet in length and the ability to cut materials up to 4 mm in thickness.

Let me provide some information on mechanical shearing machines and how they work:

Mechanical Shearing Machine: A mechanical shearing machine is a type of industrial equipment designed for cutting various materials, typically sheet metal, plates, or other flat materials. It uses a mechanical lever or flywheel mechanism to generate the force needed for cutting. The basic components of a mechanical shearing machine include the shear blades, a back gauge for positioning the material, and the mechanical or hydraulic system for applying force.

Specifications:

Cutting Length: 4 Feet This indicates that the maximum length of material that can be cut in a single pass is 4 feet.

Cutting Capacity: 4 mm This specifies the maximum thickness of the material that the shearing machine can effectively cut. In this case, it can cut materials up to 4 mm in thickness.

Working Process: Material Placement: The operator places the sheet metal or other material to be cut onto the machine's worktable.

Back Gauge Adjustment: The back gauge is adjusted to position the material correctly for the desired cut length.

Shear Blade Alignment: The shear blades are aligned to ensure a clean and accurate cut. Proper blade maintenance is crucial for achieving high-quality cuts.

Applying Force: The operator activates the mechanical mechanism (often a foot pedal or hand lever) to apply force to the shear blades.

Cutting Action: The shear blades come together, exerting pressure on the material and causing it to be sheared along the predetermined cutting line.

Material Removal: The cut pieces of material are then removed from the machine, and the process can be repeated for subsequent cuts.

Key Considerations: Material Type: Mechanical shearing machines are suitable for cutting various materials, including mild steel, stainless steel, and aluminum.

Blade Maintenance: Regular maintenance of the shear blades is essential for achieving precise and clean cuts.

Safety Measures: Operators should adhere to safety guidelines to prevent accidents during the shearing process. It's important to note that technological advancements have led to the development of hydraulic and CNC (Computer Numerical Control) shearing machines, offering increased precision, automation, and versatility compared to traditional mechanical shearing machines. The choice of the appropriate shearing machine depends on the specific requirements of the application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Shearing Machine Category

Hand Shearing

Price 14000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Hand Shearing

Automatic Grade : Manual

CNC Or Not : Not CNC, Other

Material : Steel

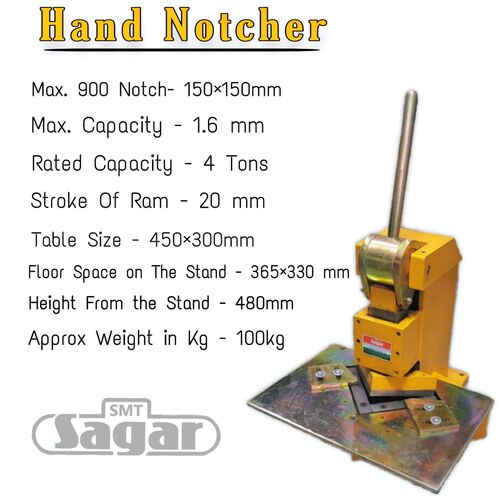

Hand Notcher

Price 26000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Hand Notcher, Other

Automatic Grade : Manual

CNC Or Not : Not CNC, Other

Treadle Shearing CI Body

Price 90000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Hydraulic Shearing Machine

Material : casting

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS