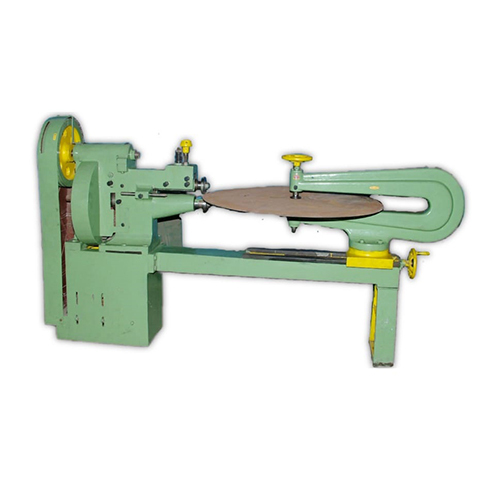

Heavy Duty Circle Cutting Machine

Price 80000 INR/ Unit

MOQ : 10 Units

Heavy Duty Circle Cutting Machine Specification

- Drive Motor

- AC Electric Motor

- Product Type

- Heavy Duty Circle Cutting Machine

- General Use

- Industrial

- Material

- Steel

- Type

- Circle Cutting Machine

- Capacity

- Variable, Suitable for Industrial Use

- Weight (kg)

- Approximately 120 kg

- Computerized

- No

- Automatic

- Yes

- Control System

- Manual

- Cutting Speed

- 2-6 m/min (Material Dependent)

- Cutting Thickness

- Up to 20 mm (Depending on Material)

- Cutting Function

- Circular Sheet & Plate Cutting

- Cooling System

- Air Cooled

- Drive Type

- Mechanical Drive

- Voltage

- 220-240 V, 50 Hz

- Dimension (L*W*H)

- 1200 mm x 700 mm x 1300 mm (Approx.)

- Feature

- Heavy Duty Structure, Adjustable Arm, Precision Cutting

- Color

- Blue and Yellow

- Motor

- 1 HP, 1440 rpm Induction Motor

- Mechanical Precision

- 1 mm tolerance

- Cutting Method

- Rotary/Disc Cutting

- Cutting Area

- 600 mm to 2000 mm (customizable)

- Cutting Material

- Steel, Stainless Steel, Aluminium Sheets

- Surface Finish

- Powder Coated Body

- Operator Requirement

- Single Operator

- Maintenance

- Low Maintenance

- Accessories

- Standard Blade, Wheel Kit for Mobility

- Safety Features

- Emergency Stop Switch, Protective Guards

- Height Adjustment

- Manual Adjustable Arm

- Power Consumption

- 0.75 - 1.2 kW

- Noise Level

- Less than 75 dB

- Installation Type

- Floor Mounted

- Gear Mechanism

- Heavy Duty Spur Gear

- Table Type

- Fixed Platform

Heavy Duty Circle Cutting Machine Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Heavy Duty Circle Cutting Machine

Get an extraordinary solution for industrial metalworking with the Heavy Duty Circle Cutting Machine! Utilise Offer and seize this hot deal engineered for perfection-ideal for precision circular cutting of steel, stainless steel, and aluminum sheets. Its uncommon heavy-duty spur gear mechanism, floor mounted design, and powder-coated finish ensure long-lasting durability, while manual height-adjustable arm and emergency stop switch guarantee safety and adaptability. The automatic mechanical drive, low-maintenance operation, and 0.75-1.2 kW power consumption make it perfect for efficient workflows. Equipped with a standard blade, wheel kit, and capable of up to 20 mm thickness cutting, this machine is suitable for dealers, exporters, manufacturers, and industrial service providers across India.

Application & Suitability Across Industries

The Heavy Duty Circle Cutting Machine is tailored for use in fabrication yards, engineering workshops, construction sites, and sheet metal processing units. Perfect for cutting tasks on steel, stainless steel, and aluminum, it ensures precise circular cuts on surfaces ranging from 600 mm to 2000 mm. Its robust platform and adjustable arm make it suitable for both routine and advanced industrial operations, accommodating diverse materials with remarkable accuracy and minimal noise.

Delivery Time, Packaging, and Export Markets

Delivery for the Heavy Duty Circle Cutting Machine is prompt, typically within 2-3 weeks after confirmed order and quotation approval. Secure packaging ensures safe shipment, safeguarding the machine from transit damage. The product holds considerable market value in export destinations including Middle East, Africa, Asia, and Europe. Our dealer and distributor network handles logistics and after-sales support for a seamless experience, enhancing reliability and customer satisfaction.

Application & Suitability Across Industries

The Heavy Duty Circle Cutting Machine is tailored for use in fabrication yards, engineering workshops, construction sites, and sheet metal processing units. Perfect for cutting tasks on steel, stainless steel, and aluminum, it ensures precise circular cuts on surfaces ranging from 600 mm to 2000 mm. Its robust platform and adjustable arm make it suitable for both routine and advanced industrial operations, accommodating diverse materials with remarkable accuracy and minimal noise.

Delivery Time, Packaging, and Export Markets

Delivery for the Heavy Duty Circle Cutting Machine is prompt, typically within 2-3 weeks after confirmed order and quotation approval. Secure packaging ensures safe shipment, safeguarding the machine from transit damage. The product holds considerable market value in export destinations including Middle East, Africa, Asia, and Europe. Our dealer and distributor network handles logistics and after-sales support for a seamless experience, enhancing reliability and customer satisfaction.

FAQ's of Heavy Duty Circle Cutting Machine:

Q: How does the Heavy Duty Circle Cutting Machine operate for circular sheet cutting?

A: The machine utilises a mechanical rotary/disc cutting method, powered by a 1 HP induction motor and heavy-duty spur gear drive, allowing for precise and consistent circular cuts on steel, stainless steel, and aluminium sheets.Q: What safety features are incorporated in this circle cutting machine?

A: Safety is ensured through multiple features including an emergency stop switch and protective guards, minimising risk during operation and helping maintain a secure workspace for the single operator.Q: Where can the Heavy Duty Circle Cutting Machine be installed?

A: Installation is floor-mounted, making it suitable for industrial sites, workshops, and fabrication plants with sufficient space for its dimensions (1200 mm x 700 mm x 1300 mm approx.).Q: What is the typical process for placing an order and receiving shipment?

A: Orders are confirmed via quotation approval, followed by shipment arranged within 2-3 weeks. Machines are delivered securely packed to safeguard against transit damages, with dealer support available throughout the process.Q: What are the benefits of using this machine for industrial applications?

A: This circle cutting machine provides precision cutting (1 mm tolerance), adjustable arm for various cutting heights, rapid operation at up to 6 m/min, reduced noise level, and reliable low-maintenance performance, making it perfect for heavy-duty industrial projects.Q: How adjustable is the cutting area to suit different project requirements?

A: The cutting area is customizable from 600 mm to 2000 mm, allowing precise adaptation to project needs, and the manual adjustable arm further enhances flexibility for different sheet sizes and thicknesses.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Circle Cutting Machine Category

Solid Circle Cutting Machine

Price 160000 INR / Unit

Minimum Order Quantity : 10 Units

Product Type : Solid Circle Cutting Machine

Dimension (L*W*H) : 1500 x 900 x 1300 mm

Type : Other, Circle Cutting Machine

Cutting Function : Other, Circular/Solid Cutting

Industrial Circle Cutting Machine

Price 160000 INR / Unit

Minimum Order Quantity : 10 Units

Product Type : Industrial Circle Cutting Machine

Dimension (L*W*H) : 1050 x 700 x 1200 mm

Type : Other, Circle Cutting Machine

Cutting Function : Other, Circle Cutting

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS