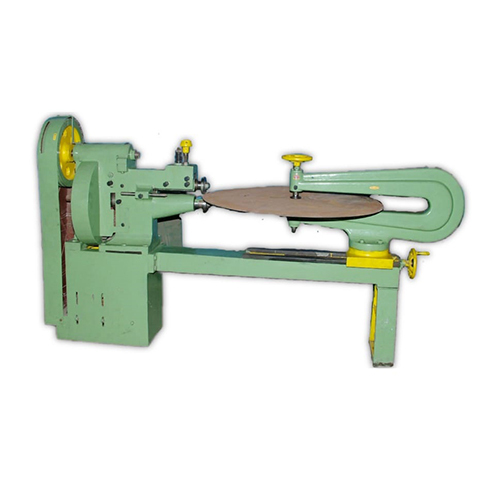

Solid Circle Cutting Machine

Price 160000 INR/ Unit

Solid Circle Cutting Machine Specification

- Drive Motor

- Induction Motor

- Product Type

- Solid Circle Cutting Machine

- General Use

- Industrial

- Material

- Steel

- Type

- Circle Cutting Machine

- Capacity

- Depends on Material and Thickness

- Weight (kg)

- Approx. 250 kg

- Computerized

- No

- Automatic

- Yes

- Control System

- Manual

- Cutting Speed

- Adjustable, up to 1500 mm/min

- Cutting Thickness

- Up to 25 mm

- Cutting Function

- Circular/Solid Cutting

- Cooling System

- Water Cooling (Optional)

- Drive Type

- Gear Drive

- Voltage

- 220V / 380V (Customizable)

- Dimension (L*W*H)

- 1500 x 900 x 1300 mm

- Feature

- Heavy Duty, Robust Construction

- Color

- Blue / Custom Available

- Motor

- 2 HP Electric Motor

- Mechanical Precision

- 0.5 mm

- Software Detail

- Not Applicable (Manual Operation)

- Cutting Method

- Rotary/Blade Cut

- Cutting Area

- Up to 600 mm diameter

- Cutting Material

- Steel (sheets, plates, circles)

- Safety Features

- Protective Blade Guard, Emergency Stop Switch

- Operator Requirement

- Single Operator

- Base Structure

- Mild Steel Fabricated Frame

- Noise Level

- Below 85 dB

- Power Consumption

- Approx. 1.5 kW

- Application

- For Cutting Solid Steel Circles, Metalworking Shops, Metal Fabricators

- Table Size

- 900 mm diameter

- Maintenance

- Low Maintenance; Easy Access Parts

- Finish Type

- Painted / Powder Coated for Rust Resistance

- Installation

- Floor Mounted

Solid Circle Cutting Machine Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Solid Circle Cutting Machine

Solid Circle Cutting Machine is demanded to cut perfect circular shapes out of solid materials such as wood, plastic, and metal. These machines are commonly used in manufacturing, carpentry, and woodworking where precision cutting is essential. The machine consists of a circular blade that rotates at high speed and cuts through the material in a circular motion. The cutting depth and diameter are adjustable, allowing for precise cuts to be made. Moreover, Solid Circle Cutting Machine is perfect for a variety of industries where circular shapes are required, and they offer greater precision and efficiency over manual cutting techniques.

Heavy-Duty Robust Construction

Built with a fabricated mild steel frame, this machine boasts unparalleled durability for continuous, heavy-duty use. The gear drive and induction motor system enable smooth, efficient cutting operations. It is specifically crafted to handle steel circles and plates, maintaining precision and consistent performance. This solid construction ensures longevity, reliability, and minimal vibration, optimizing results for demanding industrial environments.

User-Friendly Control and Safety

The Solid Circle Cutting Machine emphasizes operator safety and ease of control. It requires only a single operator thanks to its uncomplicated manual control system. Featuring a protective blade guard and an emergency stop switch, the machine prioritizes user protection during operation. Its low maintenance requirements and accessible parts further simplify upkeep, allowing for efficient production without interruptions.

FAQ's of Solid Circle Cutting Machine:

Q: How is the Solid Circle Cutting Machine installed in a workshop?

A: The machine is floor mounted and requires a stable, level surface with access to an appropriate power supply (220V/380V). Installation is straightforward, as its base structure is fabricated to ensure secure positioning and minimal vibration, supporting industrial metalworking setups.Q: What materials and thicknesses can this machine cut?

A: This machine is designed for cutting solid steel circles, sheets, and plates up to 600 mm in diameter and 25 mm in thickness. Its robust gear drive and powerful 2 HP induction motor ensure efficient cutting across a range of steel types.Q: When is the water cooling system recommended for use?

A: The optional water cooling system is advisable when operating for extended periods or cutting thicker steel materials. It helps regulate blade temperature, preventing overheating, and ensures both optimal performance and longer blade life.Q: Where is this machine best applied?

A: The Solid Circle Cutting Machine is ideal for industrial settings such as metalworking shops and fabrication facilities. Its heavy-duty design and precise cutting capabilities make it suitable for dealers, distributors, manufacturers, and service providers in the steel fabrication sector across India.Q: What steps are involved in operating the machine?

A: To operate, securely position the steel material on the table, adjust the cutting area according to diameter requirements, select desired cutting speed (up to 1500 mm/min), and initiate blade rotation using the manual control system. The protective guard and emergency stop ensure safe cutting throughout the process.Q: How does the machine provide benefits over manual cutting methods?

A: By automating the rotary cutting process, the machine offers increased precision (0.5 mm), consistent results, enhanced safety, faster production rates, and reduced physical effort for operators, ultimately improving workflow efficiency in industrial environments.Q: What maintenance procedures should users follow?

A: Routine maintenance includes cleaning metal shavings, checking blade condition, lubricating moving parts, and inspecting safety switches. The machine's design allows quick access to critical components, contributing to its low maintenance requirements and reducing downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Circle Cutting Machine Category

Heavy Duty Circle Cutting Machine

Price 80000 INR / Unit

Minimum Order Quantity : 10 Units

Motor : 1 HP, 1440 rpm Induction Motor

Product Type : Heavy Duty Circle Cutting Machine

Color : Other, Blue and Yellow

Dimension (L*W*H) : 1200 mm x 700 mm x 1300 mm (Approx.)

Industrial Circle Cutting Machine

Price 160000 INR / Unit

Minimum Order Quantity : 10 Units

Motor : 1 HP

Product Type : Industrial Circle Cutting Machine

Color : Other, Blue & Silver

Dimension (L*W*H) : 1050 x 700 x 1200 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS