Bandsaw Machinery

Price 78000 INR/ Unit

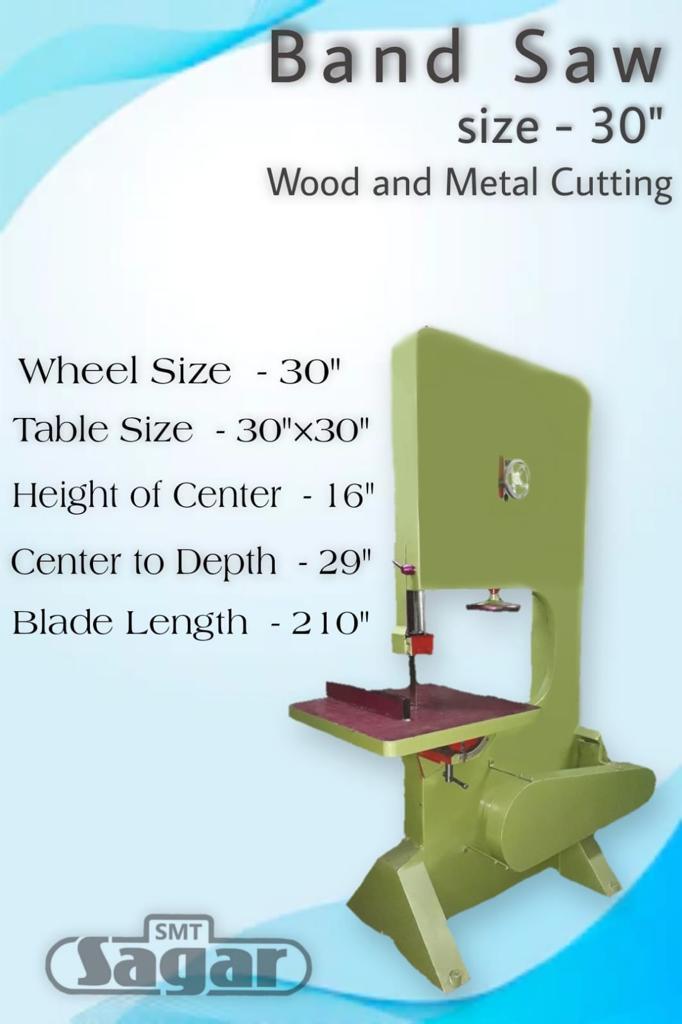

Bandsaw Machinery Specification

- Product Type

- Bandsaw Machinery

- General Use

- Industrial

- Material

- Steel

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Warranty

- 1 Year

Bandsaw Machinery Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Week

About Bandsaw Machinery

Bandsaw Machine

Wheel Sizes : 12" , 18", 24" , 30"

A bandsaw machine is a versatile and powerful tool used in woodworking, metalworking, and other industries for cutting various materials.

Here are some key features and information about bandsaw machinery:

Blade Design: The bandsaw gets its name from the continuous band or loop of toothed metal (usually a thin, flexible steel blade) that runs between two wheels. This design allows for a consistent cutting motion. Types of Bandsaws:

Woodworking Bandsaws: These are designed specifically for cutting wood and may have features like a larger table for supporting larger workpieces and different blade configurations optimized for wood cutting.

Metal-cutting Bandsaws: These are built to cut metal, and they often have a slower blade speed to handle the characteristics of metal materials.

Vertical vs. Horizontal Bandsaws: Vertical Bandsaws: These are commonly used in woodworking and are suitable for intricate cuts. They have a vertically oriented blade. Horizontal Bandsaws: These are often used for cutting metal. The blade is positioned horizontally, and the workpiece is fed through the blade. Capacity: Bandsaw machines come in various sizes, and their capacity is determined by the distance between the blade and the throat of the saw (the maximum width of the cut). Adjustability: Many bandsaw machines have adjustable features such as blade tension, blade guides, and table tilt, allowing users to make precise cuts and accommodate different materials.

Resawing: Bandsaws are commonly used for resawing in woodworking, which involves cutting a board into thinner slices. This is particularly useful for creating veneers or obtaining thinner pieces of wood. Safety Features: Safety is a crucial consideration when using bandsaw machinery.

Blade guards, blade tension indicators, and other safety features are often built into these machines to protect users.

Materials: Bandsaws are capable of cutting a wide range of materials, including wood, metal, plastic, and more. The choice of blade and machine configuration depends on the material being cut. Bandsaw machines are valued for their versatility, precision, and ability to make curved or irregular cuts. Like any machinery, users should be trained in their operation and follow safety guidelines to ensure safe and efficient use.i

Robust Manual Bandsaw Machinery for Industry

Engineered from high-grade steel, our manual bandsaw machinery is tailored for industrial settings where strength and reliability are paramount. Its manual control system allows operators to manage cutting speed and accuracy, making it suitable for both small-scale and large-scale production environments. This machinery is distributed throughout India by trusted professionals in the field.

Versatile Applications Across Sectors

From manufacturing to metalworking and fabrication, our bandsaw machines find utility in diverse industrial processes. Their adaptability and straightforward operation make them the preferred choice for businesses that prioritize efficiency and precision without relying on automated or computerized systems.

FAQ's of Bandsaw Machinery:

Q: How does a manual bandsaw machine operate in industrial settings?

A: A manual bandsaw machine operates by allowing the user to control the cutting process manually, adjusting the speed and movement as needed. This hands-on approach gives operators precision and flexibility for various industrial applications.Q: What materials can be cut using this manual bandsaw machinery?

A: This bandsaw machinery is primarily constructed from steel and is capable of cutting a wide range of materials, including various metals and hard plastics commonly used in industrial workshops and manufacturing processes.Q: When is it recommended to use a non-automatic, non-computerized bandsaw machine?

A: A manual bandsaw is recommended when operators require greater hands-on control, customized cutting angles, or need a reliable machine for batch production and one-off projects. It is also advantageous in settings with variable cutting requirements.Q: Where can I purchase or source this bandsaw machinery in India?

A: You can acquire this bandsaw machinery through reputable dealers, distributors, manufacturers, suppliers, traders, wholesalers, and retailers spread across India, providing both regional and nationwide supply options.Q: What is the process for installation and maintenance of the bandsaw machine?

A: Installation is straightforward and typically managed by the supplier or service provider. Maintenance includes regular cleaning, lubrication, blade checks, and timely replacement of worn parts, ensuring optimal performance throughout the warranty period.Q: How is this machinery beneficial for industrial users?

A: Manual bandsaw machinery offers industrial users cost-effectiveness, dependable performance, easy operation, and precise control over cuts. It eliminates the need for complex automated systems, making it suitable for businesses focused on productivity and accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS