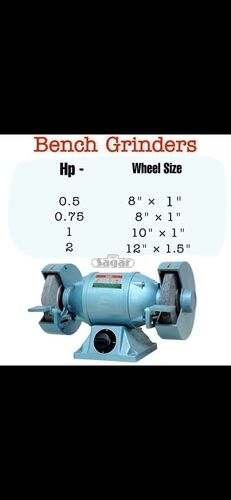

Bench Grinders

Price 7000 INR/ Unit

Bench Grinders Specification

- Cooling System

- Optional Water Tray

- Accuracy

- Standard Industrial Tolerance

- Motor Power

- 0.5 HP to 2 HP

- Power Rating

- 0.37 kW to 1.5 kW

- Frame Type

- Cast Iron

- Model No

- BG Series

- Voltage

- 220V/415V

- Features

- Heavy Duty Body, Dust Resistant, Vibration Free

- Noise Level

- Below 70 dB

- Production Capacity

- Continuous Operation

- Drive

- Direct Drive

- Control System

- Manual Switch On/Off

- Operating Temperature

- 0C to 45C

- Machine Type

- Bench Grinder

- Frequency

- 50 Hz

- Lubricating System

- Self-Lubricating Bearings

- Product Type

- Bench Grinder

- Technology

- Conventional

- Power Source

- Electric

- Operating Type

- Semi-Automatic

- Power

- 0.5 HP to 2 HP

- Surface Treatment

- Paint Coated

- Dimension (L*W*H)

- Varies by Model (e.g., 350x200x250 mm to 500x300x350 mm)

- Weight (kg)

- Approx. 20-45 kg

- Color

- Green/Blue/Custom

- Usage & Applications

- Grinding, Sharpening, Deburring, Polishing

Bench Grinders Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Bench Grinders

Sagar Machine Tools

We are Leading Manufacturer of Bench GrindersA bench grinder is a versatile and widely used tool in workshops, garages, and metalworking environments. It is a stationary machine mounted on a bench or pedestal, equipped with abrasive wheels for various grinding, sharpening, and shaping tasks. Bench grinders are commonly used to sharpen tools, remove rust or burrs from metal, and perform other tasks that involve grinding or shaping materials.

Here are key features and aspects of bench grinders:

Motor and Power: Bench grinders are typically powered by an electric motor. The power of the motor can vary, and higher horsepower allows for more efficient grinding and handling larger workpieces.

Grinding Wheels: Bench grinders are equipped with one or more grinding wheels. These wheels are typically made of abrasive materials like aluminum oxide or silicon carbide. The wheels come in different grit sizes for various applications, ranging from coarse to fine.

Wheel Guards: For safety reasons, bench grinders are fitted with wheel guards that cover the grinding wheels. These guards protect the user from sparks, debris, and potential wheel breakage.

Tool Rests: Tool rests are adjustable platforms that support the workpiece during grinding. They help maintain a consistent angle and distance between the grinding wheel and the workpiece, aiding in precision.

Spark Deflectors: Spark deflectors are additional safety features that help direct sparks away from the user and the surrounding area. Adjustable Speed: Some bench grinders come with adjustable speed settings, allowing users to control the grinding speed based on the specific task or material. Coolant Tray: Some industrial bench grinders include a coolant tray to prevent the workpiece and grinding wheel from overheating during prolonged use. Coolant can be added to the tray to lubricate and cool the grinding process.

Applications: Bench grinders are used for a variety of tasks, including sharpening tools (such as chisels, drill bits, and knives), removing burrs or rust from metal, and shaping or polishing metal surfaces. Safety Considerations: Safety is crucial when using a bench grinder. Users should wear safety glasses to protect their eyes from debris and sparks. Additionally, proper safety precautions, such as using the wheel guards and following manufacturer guidelines, should be observed. Maintenance: Regular maintenance, such as checking for wheel wear and ensuring the tool rests are properly adjusted, is important for the safe and effective operation of a bench grinder. Bench grinders are available in various sizes and configurations, and the choice of a specific model depends on the intended applications and the users requirements. They are widely used in metalworking, woodworking, and general maintenance tasks.

Versatile Applications

The BG Series Bench Grinders are engineered for diverse uses such as grinding, sharpening, deburring, and polishing. Whether in tool rooms, workshops, or industrial environments, these machines adapt to a wide range of materials and workpieces, making them a staple in maintenance and fabrication settings.

Rugged Construction & Safety

Featuring a heavy-duty cast iron frame and vibration-free operation, these grinders offer durability and stable performance. Safety is prioritized with included guard covers, spark arrestors, and rocker switches for easy control. The base is bolt-mounted to ensure secure installation during continuous operation.

Customizable & International Standards

Available in different colors and sizes, each model meets IS:916 and ISO certifications, and is produced for both Indian and global markets. Accessories included such as grinding wheels and tool rests enhance operational convenience and maximize productivity.

FAQs of Bench Grinders:

Q: How do I select the right wheel diameter for my bench grinder application?

A: Choose based on the material type and task150 mm wheels suit light grinding and sharpening, while 200 mm or 250 mm wheels provide a larger surface area for more intensive grinding or frequent use.Q: What are the benefits of having two grinding wheels?

A: Two wheels enable users to switch between different grit sizes or materials without changing wheels, improving workflow and efficiency in multi-purpose tasks such as sharpening and deburring.Q: Where can these bench grinders be installed?

A: They are designed for secure bolt-on installation on flat workbenches in industrial workshops, maintenance rooms, fabrication sites, or manufacturing facilities.Q: What safety features are included with the BG Series grinders?

A: Each model comes with guard covers, spark arrestors, stable tool rests, and a rocker switch, ensuring user safety during operation.Q: How does the self-lubricating bearing system benefit the user?

A: It minimizes maintenance needs by ensuring smooth wheel rotation and prolonging the grinders lifespan.Q: When is it necessary to use the optional water tray cooling system?

A: The water tray should be used for prolonged grinding sessions or when working with heat-sensitive materials to prevent overheating and maintain edge integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS