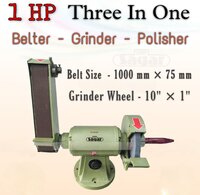

Abrasive Belt Grinding Machines

Product Details:

Abrasive Belt Grinding Machines Price And Quantity

- 36000 INR/Unit

- 1 Unit

- 36000.00 - 46000.00 INR/Unit

Abrasive Belt Grinding Machines Trade Information

- Cash Advance (CA) Cash in Advance (CID)

- 10 Unit Per Month

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

Product Description

Sagar Machine Tools

We are Manufacture of All Type of Abrasive Grinding Machine

Abrasive belt grinding machines are industrial machines that use coated abrasive belts to remove material from a workpiece. These machines are commonly used in metalworking, woodworking, and other manufacturing applications for tasks such as deburring, surface finishing, and shaping. Here are some key features and functions of abrasive belt grinding machines:

Abrasive Belt:

These machines use abrasive belts made of coated abrasives, such as aluminum oxide, silicon carbide, or zirconia alumina. The abrasive belt is wrapped around rotating drums or pulleys.

Belt Tracking and Tensioning:

Abrasive belt grinding machines typically have mechanisms for tracking and tensioning the abrasive belt. This ensures that the belt stays properly aligned and tensioned during the grinding process.

Contact Wheel:

The abrasive belt makes contact with a rotating contact wheel or worktable. The choice of contact wheel size and material affects the grinding performance and finish.

Variable Speeds:

Many abrasive belt grinding machines have variable speed controls, allowing operators to adjust the belt speed based on the material being processed and the desired finish.

Workpiece Fixturing:

Workpieces are usually secured on a worktable or fixture during the grinding process. The worktable may be adjustable in different directions to accommodate various shapes and sizes of workpieces.

Wet or Dry Grinding:

Depending on the application and machine design, abrasive belt grinding machines may perform wet or dry grinding. Wet grinding is often used to reduce heat and control dust during the grinding process.

Dust Extraction:

Dust extraction systems are commonly integrated into abrasive belt grinding machines to remove and collect the dust generated during the grinding process, improving workplace safety and maintaining a clean working environment.

Applications:

Abrasive belt grinding machines are used for a variety of applications, including deburring, edge rounding, surface finishing, stock removal, and shaping of metal, wood, plastics

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS