Drilling Cum Milling Machine

Price 62000 INR/ Unit

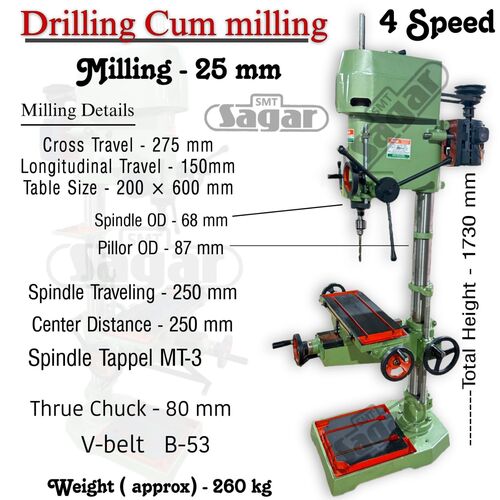

Drilling Cum Milling Machine Specification

- Product Type

- Drilling Cum Milling

- Computerized

- No

- CNC Or Not

- Normal

Drilling Cum Milling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Drilling Cum Milling Machine

Sagar Machine Tools

A drilling cum milling machine, also known as a mill drill machine, is a versatile tool that combines the functions of both drilling and milling. It's a machine tool used for various machining operations, and here are some key features and information about it:

Combination of Operations:

Drilling: The machine can perform drilling operations, creating holes in workpieces using a rotating cutting tool (drill bit).

Milling: It can also perform milling operations, which involve removing material from the workpiece using a rotating multi-point cutting tool (end mill).

Versatility: The drilling cum milling machine is versatile, making it suitable for a range of tasks. It's commonly used in workshops for tasks such as drilling, milling, reaming, and counterboring.

Structure: The machine typically consists of a column, a base, an overarm, a spindle with a drill or milling cutter, and a worktable. The worktable can be adjusted and moved to accommodate different workpiece sizes.

Power Source: These machines can be powered manually, but more commonly, they are equipped with an electric motor for automated and efficient operation.

Adjustability: Users can often adjust the machine to control the depth and speed of both the drilling and milling operations. This adaptability is useful for different materials and machining requirements.

Applications: Drilling cum milling machines are used in various industries, including manufacturing, metalworking, and woodworking. They are suitable for creating holes, slots, and complex shapes in a variety of materials.

Safety Features: Like any machine tool, safety features such as guards, emergency stop buttons, and proper training for operators are crucial to ensure safe use.

Size and Capacity: These machines come in different sizes and capacities, depending on the specific needs of the user. The capacity is often defined by factors such as the maximum size of the workpiece that can be accommodated.

Cost and Complexity: The cost and complexity of drilling cum milling machines can vary based on factors like size, features, and precision. Smaller, benchtop models may be suitable for lighter tasks, while larger, industrial-grade machines can handle more substantial work.

In summary, the drilling cum milling machine is a versatile machining tool that combines drilling and milling functions. It provides flexibility for a range of machining tasks and is commonly used in workshops and manufacturing settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Drill Machine Category

32mm Pillar Drill Machine

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Automatic Grade : SemiAutomatic

Computerized : No

CNC Or Not : Normal

19mm Pillar Drill Machine

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Automatic Grade : SemiAutomatic

Computerized : No

CNC Or Not : Normal

25mm Pillar Drill Machine

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Automatic Grade : SemiAutomatic

Computerized : No

CNC Or Not : Normal

Heavy Duty Chuck Type Drill Machine

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Automatic Grade : SemiAutomatic

Computerized : No

CNC Or Not : Normal

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS