Press Brake

Price 180000 INR/ Unit

MOQ : 1 Unit

Press Brake Specification

- Sheet Size

- Up to 6 mm Thick

- Automation Grade

- Semi-Automatic

- Application

- Sheet Metal Bending

- Voltage

- 415 V

- Cutting Size

- Up to 2500 mm

- Frequency

- 50 Hz

- Bending Strength

- 80 Ton

- Strokes Per Min

- 10

- Motor Power

- 7.5 HP

- Features

- Rigid Construction, Easy Operation, Low Maintenance

- Stroke Length

- 100 mm

- Material

- Mild Steel

- Accuracy

- 0.5 mm

- Working Table Width

- 250 mm

- Overall Length

- 3200 mm

- Press Brake Type

- Hydraulic

- Number of Cylinders

- 2

- Frame Type

- Fabricated Steel

- Control Type

- Push Button / Foot Switch

- Back Gauge System

- Manual / Motorized

- Color

- Blue & White

About Press Brake

Experience the extraordinary with our Hydraulic Press Brake, showcasing an unbeatable combination of precision and strength. With a breathtaking bending capacity of 80 tons and engineered on a fabricated steel frame, this ephemeral offer is highly recommended for anyone seeking reliable sheet metal bending solutions. The robust design features twin cylinders, manual/motorized back gauge, and a semi-automatic control system, making it an ideal choice for dealers, distributors, and service providers across India. This press brake delivers 0.5 mm accuracy, easy operation, and low maintenance-perfect for professional-grade results.

Press Brake: Site of Application & Usage

This versatile Press Brake is highly suitable for use in heavy-duty sheet metal bending operations at manufacturing plants, fabrication workshops, and industrial job sites. Widely used as a core machine for precise bending of mild steel sheets, the machine is recommended for forming components up to 6 mm thick with a cutting size of up to 2500 mm. Ideal for producers, traders, and service providers needing reliable and efficient sheet metal solutions.

Payment Terms, Certifications, and Sample Policy

Purchase this Press Brake with flexible payment terms ensuring secure shipping and unbeatable freight rates. We guarantee the lowest price for certified machinery meeting stringent national and international quality standards. Samples can be arranged to demonstrate machine capability and ensure customer satisfaction prior to full order placement. This policy aims to provide transparency and reliability from manufacturer to wholesaler.

Press Brake: Site of Application & Usage

This versatile Press Brake is highly suitable for use in heavy-duty sheet metal bending operations at manufacturing plants, fabrication workshops, and industrial job sites. Widely used as a core machine for precise bending of mild steel sheets, the machine is recommended for forming components up to 6 mm thick with a cutting size of up to 2500 mm. Ideal for producers, traders, and service providers needing reliable and efficient sheet metal solutions.

Payment Terms, Certifications, and Sample Policy

Purchase this Press Brake with flexible payment terms ensuring secure shipping and unbeatable freight rates. We guarantee the lowest price for certified machinery meeting stringent national and international quality standards. Samples can be arranged to demonstrate machine capability and ensure customer satisfaction prior to full order placement. This policy aims to provide transparency and reliability from manufacturer to wholesaler.

FAQ's of Press Brake:

Q: How does the manual or motorized back gauge system enhance work accuracy?

A: The manual or motorized back gauge system allows precise adjustment and positioning of the sheet metal, ensuring repeatable accuracy within 0.5 mm for consistent bends every cycle.Q: What is the recommended process for operating the press brake safely?

A: Operators should follow safety protocols by using the push button or foot switch controls, wear appropriate protective gear, and ensure the sheet's thickness and size match machine specifications before initiating a bending cycle.Q: Where can this hydraulic press brake be effectively applied?

A: This press brake is ideal for manufacturers, fabricators, and service providers who need reliable bending solutions for mild steel sheets in industries such as construction, automobile, and heavy machinery.Q: What are the benefits of choosing this semi-automatic hydraulic model?

A: Its semi-automatic system ensures easy operation, lower maintenance costs, and precise bending with strong, reliable construction-making it highly recommended for demanding production environments.Q: How does the sample policy ensure buyer confidence?

A: Sample policies allow potential buyers to evaluate machine performance and capabilities, ensuring satisfaction before placing a full order, thus building trust and assuring quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydraulic Press Brakes Category

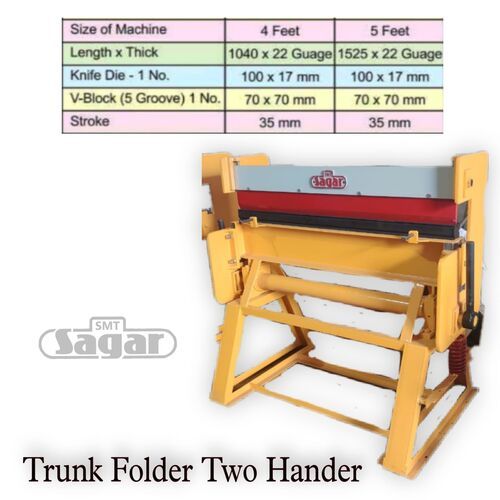

Trunk Folder Two Hander

Price 55000 INR / Unit

Minimum Order Quantity : 1 Unit

Stroke Length : Adjustable

Frequency : 50 Hz

Cutting Size : Up to 32 inches

Features : Double hand operated, powder coated finish, userfriendly design, rigid frame

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS